Sun, 27 Nov 2016 14:23:00 -0800

Brewing "The Bitter End" ESB...

I've been wanting to brew an ESB for a while now. I stumbled across a recipe called that people rave about, so I thought I'd tweak it a bit and try it out.

The recipe calls for Maris Otter malt as the base, but I couldn't find that in organic, so I went with organic Crisp malt, which is similar, but whereas the Maris Otter is a bit more bread-tasting, the Crisp is more "biscuity". I also subbed in American variants for the English hops, and C60 malt instead of C55. I stuck with a traditional ESB yeast, though.

I figured I'd do a photo timeline of the all-grain brew day (or most of it anyways), so here goes...

Heated the strike water; I use an outdoor propane burner:

Mashing in! Stirring the grains into the strike water:

Adding the specialty grains:

For the mash rest, I need to maintain a constant precise temperature. It helps to insulate the mash tun:

Insulating it really well helps:

I'm a "brew-in-a-bag" brewer, as it keeps things neat and easy for these small batches. Once the mash is done, I drain the grain bag through a colander:

And then "sparge" with hot water:

#BrewDay #ESB #BitterEnd

#BrewDay #ESB #BitterEnd

kelly jacklin

Sun, 27 Nov 2016 19:56:50 -0800

Boiling the wort...

Once the mash is done, it's time for the boil. I raise the temperature of the wort (that's the term for unfermented beer):

until is is boiling:

The hops get added at various stages for bittering, flavour and aroma:

Once the boil is complete, I cool it down with an immersion chiller (sorry, I didn't get a picture of this step), which is basically a copper coil that you plop in the wort, and run tap water through to act as a heat exchanger to leach out the heat from the wort.

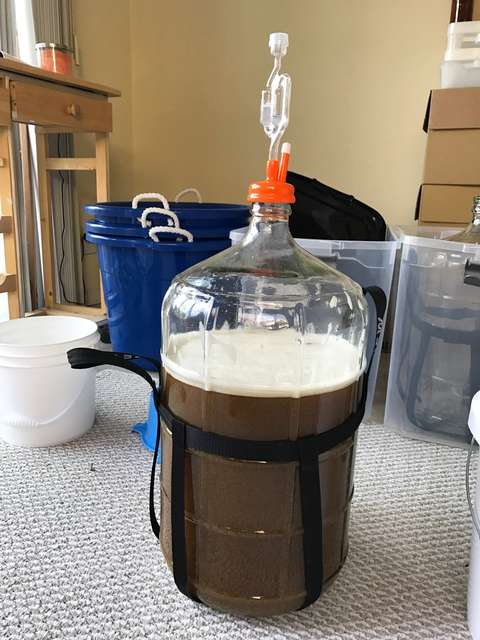

The cooled-down wort then sits in a sanitized fermenting carboy for a bit:

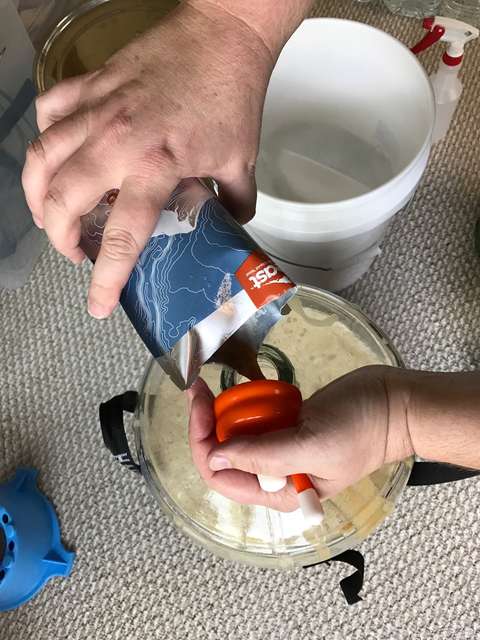

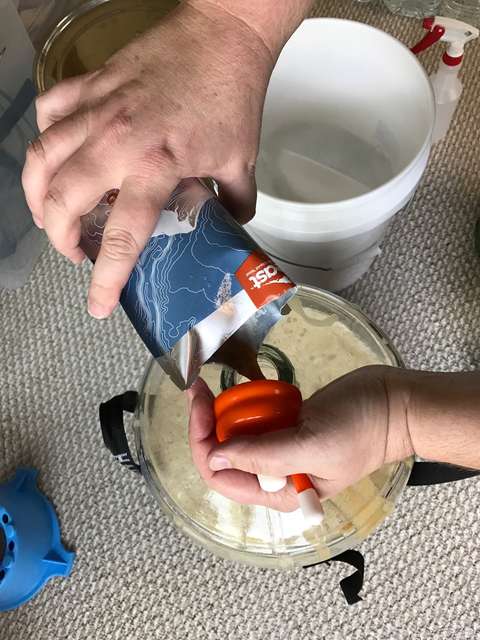

And then we pitch the yeast:

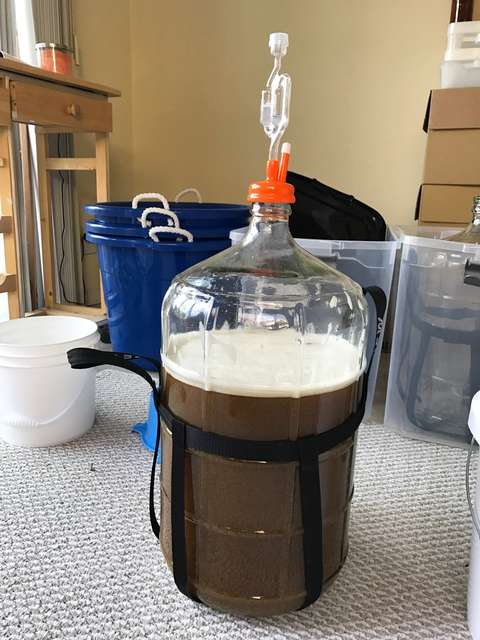

Finally, we add an airlock, so the yeasts can off-gas (erm, fart) carbon dioxide, but nothing gets back into the fermenting beer:

At this point, our work is done (well, mostly), but the yeasts' work has just begun...

And when I say our work is done, I really mean that it, too, has only just begun... As much time as I spend brewing, I spend the same amount, or perhaps even more, cleaning up. The brew kettle is a bit mess to clean up, with beer stone from the baked-on hops and protein break, and everything else needs a good scrubbing as well, so we can be ready for the next brewing day...

kelly jacklin

Mon, 28 Nov 2016 07:47:51 -0800

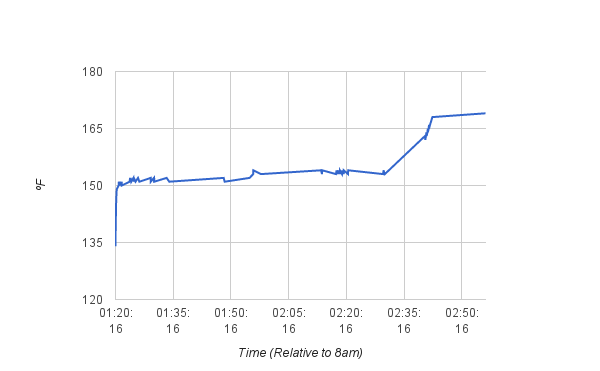

Mash temperature chart...

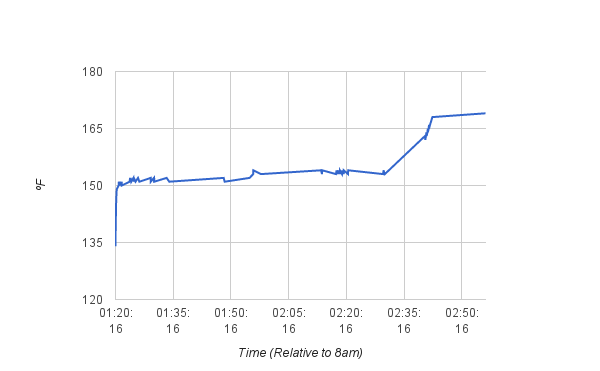

Chart of mash temperatures over time:

(For some reason I cannot explain, Google Sheets decided to adjust my times by 8 hours, even when I edited the timezone to GMT... And iWork Numbers will not let me do a non-linear plot against time, so that's why I resorted to Google Sheets...)

kelly jacklin

Mashing in! Stirring the grains into the strike water:

Mashing in! Stirring the grains into the strike water:

Adding the specialty grains:

Adding the specialty grains:

For the mash rest, I need to maintain a constant precise temperature. It helps to insulate the mash tun:

For the mash rest, I need to maintain a constant precise temperature. It helps to insulate the mash tun:

Insulating it really well helps:

Insulating it really well helps:

I'm a "brew-in-a-bag" brewer, as it keeps things neat and easy for these small batches. Once the mash is done, I drain the grain bag through a colander:

I'm a "brew-in-a-bag" brewer, as it keeps things neat and easy for these small batches. Once the mash is done, I drain the grain bag through a colander:

And then "sparge" with hot water:

And then "sparge" with hot water:

#BrewDay #ESB #BitterEnd

#BrewDay #ESB #BitterEnd

until is is boiling:

until is is boiling:

The hops get added at various stages for bittering, flavour and aroma:

The hops get added at various stages for bittering, flavour and aroma:

Once the boil is complete, I cool it down with an immersion chiller (sorry, I didn't get a picture of this step), which is basically a copper coil that you plop in the wort, and run tap water through to act as a heat exchanger to leach out the heat from the wort.

The cooled-down wort then sits in a sanitized fermenting carboy for a bit:

Once the boil is complete, I cool it down with an immersion chiller (sorry, I didn't get a picture of this step), which is basically a copper coil that you plop in the wort, and run tap water through to act as a heat exchanger to leach out the heat from the wort.

The cooled-down wort then sits in a sanitized fermenting carboy for a bit:

And then we pitch the yeast:

And then we pitch the yeast:

Finally, we add an airlock, so the yeasts can off-gas (erm, fart) carbon dioxide, but nothing gets back into the fermenting beer:

Finally, we add an airlock, so the yeasts can off-gas (erm, fart) carbon dioxide, but nothing gets back into the fermenting beer:

At this point, our work is done (well, mostly), but the yeasts' work has just begun...

And when I say our work is done, I really mean that it, too, has only just begun... As much time as I spend brewing, I spend the same amount, or perhaps even more, cleaning up. The brew kettle is a bit mess to clean up, with beer stone from the baked-on hops and protein break, and everything else needs a good scrubbing as well, so we can be ready for the next brewing day...

At this point, our work is done (well, mostly), but the yeasts' work has just begun...

And when I say our work is done, I really mean that it, too, has only just begun... As much time as I spend brewing, I spend the same amount, or perhaps even more, cleaning up. The brew kettle is a bit mess to clean up, with beer stone from the baked-on hops and protein break, and everything else needs a good scrubbing as well, so we can be ready for the next brewing day...

(For some reason I cannot explain, Google Sheets decided to adjust my times by 8 hours, even when I edited the timezone to GMT... And iWork Numbers will not let me do a non-linear plot against time, so that's why I resorted to Google Sheets...)

(For some reason I cannot explain, Google Sheets decided to adjust my times by 8 hours, even when I edited the timezone to GMT... And iWork Numbers will not let me do a non-linear plot against time, so that's why I resorted to Google Sheets...)